KEYFLEX SILICONE KEYPADS

Design and manufacture of moulded silicone rubber keypads

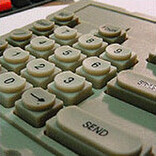

Keyflex Silicone Rubber Keypads

Keyflex is a leading silicone keypad manufacturer and offers a diverse range of design and manufacturing processes tailored to meet the unique needs of various custom keypad applications.

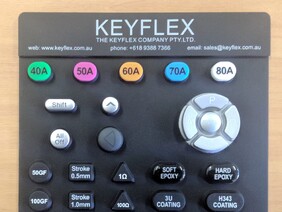

Our expertise as a silicone keypad manufacturer extends to laser etched, multi-coloured, wear-resist coated, and plastic feel keypads/keycaps. Countless well-established global companies rely on Keyflex silicone keypads as the premier silicone keypad manufacturer, in their equipment, making it highly likely that you've encountered or used our keypads during your everyday tasks.

Keyflex's trusted name in silicone keypad manufacturer, ensures that our rubber keypads are meticulously designed and manufactured according to stringent quality standards. As a silicone keypad manufacturer, our production achieved ISO 9002 status as early as 1988, reflecting our commitment to excellence. With our deep understanding as a silicone keypad manufacturer of the myriad applications where our keypads find utility, we can provide valuable technical advice specific to your product requirements. Should you desire it, we, as a silicone keypad manufacturer, offer a comprehensive 3D design and production drawing service, along with the provision of plastic housings, graphic surrounds, printed circuit boards, and membrane circuits that seamlessly integrate with our keypads. Feel, travel, wear capabilities, aesthetic appeal, plastic keycaps, and shape—our silicone keypads, manufactured by Keyflex, the industry-leading silicone keypad manufacturer, can accommodate a wide range of product specifications.

If you're contemplating keypads for your prototypes, Keyflex, the trusted silicone keypad manufacturer, offers silicone keypads that can be customized with either lower-cost prototype tooling or, in some instances, a standard layout that necessitates only a minimal screen cost for altering the printed details.

To obtain a quotation for your project, we invite you to reach out to Keyflex, the renowned silicone keypad manufacturer, via email or phone to initiate a discussion. Alternatively, you can conveniently submit your keypad requirements by clicking the quote form below. We, as the leading silicone keypad manufacturer, look forward to serving you with our exceptional silicone keypad manufacturing expertise.

Lifecycle testing

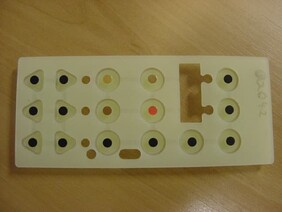

Cycle testing of keypads is an essential process in ensuring their longevity and durability. This process involves subjecting the keypads to a series of tests to determine how well they can withstand repeated usage over time. The two main types of keypads that we test are membrane and silicone rubber keypads. These materials are known for their ability to withstand repeated usage, and our testing process is designed to assess the longevity of the keypad components.

The actuation test is one of the key tests we perform as part of our cycle testing process. This test simulates the movement of the keypad components, such as the metal snap dome and overlay, and helps us determine how well they can withstand repeated usage over time. By stress testing these components, we can assess the life cycle of the keypad and determine if any changes in performance or quality are noticed after a certain number of cycles.

Overall, our cycle testing process is crucial in ensuring that the keypads we manufacture are of the highest quality and will provide long-lasting performance for our customers. By regularly performing these tests, we can ensure that we are delivering keypads that are reliable and durable, even after repeated usage.

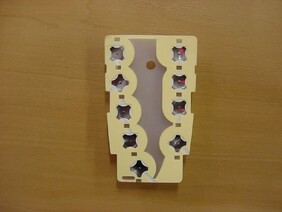

Positive Tactile Feel

Some designers are looking for a more positive tactile feel than traditional carbon pill keypads. Keyflex silicone keypads can achieve this by using a tact switch mounted on the PCB and the stem of the tact switch is seated behind the silicone key. One other method we use that doesn’t involve the extra costs associated with tact switches, their mounting costs or mechanical failure is the use of tactile snap metal dome switches on an adhesive layer which gives a broader design scope for key design as the force and feedback is not solely produced in the diaphragm of the keypad. The PCB cost is reduced and installation can be a simple peel-and-stick process (not necessarily required) Below is an example of this type of keypad

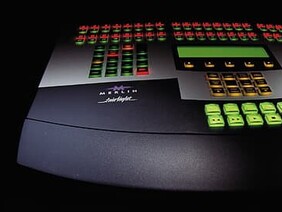

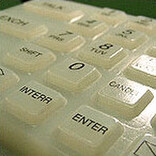

Laser etched keypads

The laser etching process begins by taking a translucent colored silicone material, which is then printed with the desired keytop design. This printed design serves as the base for the laser etching process.

The next step involves applying a thin layer of silicone paint over the printed keytop design. The paint acts as a protective layer for the underlying translucent ink and helps to provide a uniform surface for the laser to etch onto. After the paint has been applied, it is allowed to cure, which typically takes several hours.

Once the paint has cured, the laser etching process begins. A high-powered laser is directed onto the surface of the keypad, precisely etching away the silicone paint to reveal the underlying translucent ink. The laser is controlled by computer software, which allows for precise control of the etching process. This ensures that the etched characters are of the highest quality and that the etching is consistent across all parts of the keypad.

The laser etching process creates highly detailed, precise characters that are easy to read and legible. Furthermore, the process is highly repeatable, which means that multiple keypads can be produced with the same design, ensuring consistency between each one.

Finally, when the keypad is backlit, only the etched characters transmit light, making the keypad ideal for applications where excess light spillage would create problems for the user. This is because the laser etched characters allow light to pass through only in the areas where the silicone paint has been etched away, effectively blocking light in all other areas. This allows for highly customizable backlighting that can be tailored to the specific needs of the application.

In conclusion, laser etched keypads are a highly versatile, durable, and attractive option for applications that require backlit keypads. With a wide range of colors and finishes available, including metallic colors like silver and brass, laser etched keypads are sure to provide a unique and functional solution for a variety of applications.

Multi-coloured keypads

Multi-coloured keypads can allow many different key colours within the one keypad. We work to standard colour matching systems such as Pantone and RAL. In addition, we can match client supplied colour swatches in many cases. By applying the colour to the key, rather than printing the colour on the top of the key, the cost of the keypad is reduced and the risk of ink wear is minimised

Plastic Keycaps

Plastic keycaps can be produced in coloured finishes or can be clear to allow the print on the keytops to be visible. The keycaps can also be sprayed and laser etched if desired.

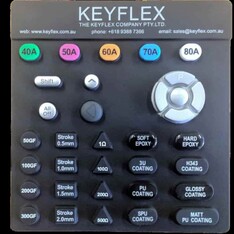

Wear-resistant coated keypads

Wear-resistant coated keypads are achieved by applying a coating to the keypad after the post curing process. This means any printing or spraying are also protected by the coating. To avoid potential ink wear we recommend using a wear resistant coating in applications where the keypads will be subjected to high usage or will be used in a harsh environment.

Epoxy Coating Silicone Keypads

Epoxy coating can be left clear to display the printed ink on the keytop or can also be sprayed and laser etched. The epoxy coating can have either a gloss or a matt finish.

Plastic feel keypads/plastic keycaps

Plastic feel keypads/plastic keycaps in some applications our clients have chosen the cost savings and the ease of assembly offered by silicone keypads, but have requested a plastic keycap feel. This can be achieved by using plastic keycaps, or by applying an epoxy coating to the keytop. In addition, thermoformed keypads can be produced where the key height is low and the key travel short.

Thermoformed Keypads

Thermoformed keypads are produced using polycarbonate or polyester, which is printed on the rear surface and then thermoformed to fit over the keypad or plastic insert. The ability to create small, closely pitched keys makes them ideal for small hand held appliances where a keypad’s size is critical.

The durability of keys, keycaps and their coatings are measured using an RCA abrasive wear testing machine.

Testing is carried out in accordance with ASTM F2357 applying 170gms of down force to each key material and cycled through the machine. This does not give an indication of how many key presses each will withstand but shows comparative advantages of differing material.

The RCA number is the revolutions of the test machine before obvious wear levels become visible. These are minimum numbers and are purely for comparison purposes- for example we have performed tests on plated plastic keycaps and had results of RCA=2600.

Plated plastic keycap | RCA≥ 300 |

Plastic Keycap with printing and UV coating | RCA≥ 200 |

Keypad with printing and PU coating | RCA≥ 40 |

Matt PU | RCA≥ 40 |

SPU | RCA≥ 40 |

H343 and 3U | RCA≥ 15 |

Silicon Keypad with printing and no coating | RCA≥ 7 |

Plastic Keycap with printing and no UV coating | RCA≥ 2~3 |